Air Atomising Nozzles for Coating

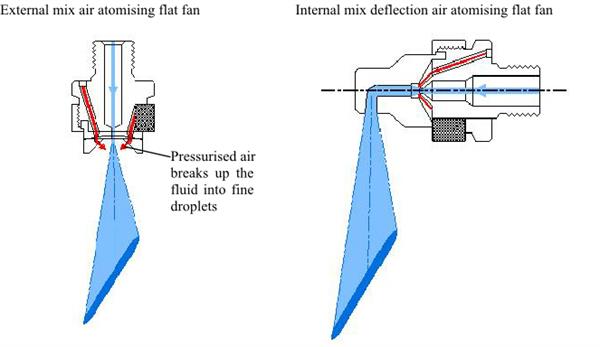

These nozzles use a secondary fluid or gas to break up the primary spraying fluid into an exceptionally fine spray. The secondary fluid is usually air, but can be any gas, but the term air atomising is used for all.

Air atomising nozzles can be used to produce evenly distributed, finely atomised full cone or flat fan or in a range of spray angles. This makes them ideal for many coating applications.

The main advantage of these over direct pressure nozzles is that they can form a spray pattern with very low flow rates. With impingement, spiral, and whirl chamber designs of nozzle the energy required to break up the fluid flow into spray pattern comes directly from the fluid being sprayed. This means that there is a natural restriction in minimum flow rates. With air atomisation a secondary source of kinetic energy is introduced in the form of pressurised gas. This is used to break up the fluid into a spray pattern. As such, fine atomisation and spray patterns can be maintained with much lower fluid flows from this type of nozzle.

For coating applications the standard XA series of air atomising nozzles can be used, but for high precision coating the SAM series of air atomisers give far greater control. These advanced twin fluid nozzles have two independent air feeds - one to atomise the fluid just as in standard air atomisers and the second is used to shape the spray pattern. This gives an unparallelled level of control for very precise spraying making them perfect for coating applications. As the SAM allows the shape and droplet size of the spray to be varied independent of flow rate its means that product runs of different sizes and shapes can be dealt with by the same nozzle.

Summary

To access full product information on any of the ranges of air atomising nozzles please click on the product boxes below.

For coating applications that require a flat fan spray pattern the XApf or XAff range of nozzles would be a good choice.

For applications that require a full cone pattern the XApr would an a sensible choice.

For spraying viscous fluids external mix variants of the XA air atomisers would be advisable. For flat fans this would be the XAef and for full cones this would be the XAer.

If very low flow rates for fine coatings are required then the siphon fed XAsr allows for flow rates as low as 0.5 litres per hour.

For high precision spraying or spraying that might need to be varied regularly for different product runs the SAM range of nozzles would be the best choice.