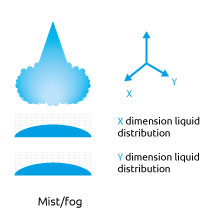

Misting / fog

One further pattern, which is not a true pattern per se but is the spray created by misting nozzles, should also be included in any discussion of sprays.

Misting nozzles form a homogeneous fog or mist with little or no impact. The pattern will start out as a full or hollow cone but at a very short distance from the nozzle orifice the pattern will loose coherence and form a fog or mist.

Many hollow and full cone nozzles will eventually form a mist if sprayed at sufficient pressures. But there are two designs of nozzle that seek to achieve misting deliberately.

- The small orifice nozzle will operate at high pressures pushing fluid through a very small opening to break it apart into a fog.

-The impingement nozzle will impact a stream of fluid onto a pin directly below the orifice. This literally smashes the fluid apart into a fog.

See different spray patterns in the nozzles in action videos below