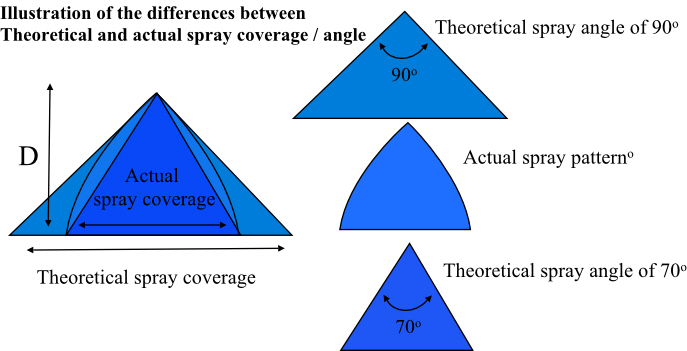

Actual patterns vs theoretical pattern

Why is this important?

Often only a specific area will need to be targeted with a spray and so the overall pattern needs to be calculated. The theoretical spray pattern calculated by basic trigonometry will often be different from what happens in reality.

Factors to consider

The effects of wind and gas flow

This will clearly affect the resultant pattern. The amount of drift that will occur will depend upon the droplet size, spray momentum and, of course, the direction of spray. This can be hard to calculate but we have software that can swiftly approximate likely spray patterns in a gas flow of a known speed and direction.

The effects of gravity

The idealised geometric cones and fans will only hold for a certain distance from the orifice. How long the pattern holds will depend on the nozzle being used, the flow rates and the pressure but at a certain distance gravity starts to curve in the spray pattern resulting in a smaller impact area than the theoretical pattern. Again this can be hard to calculate so specialist software may need to be deployed.

The general principle is illustrated below.

As distance D increases any spray pattern will degrade further from the theoretical. How quickly this degradation occurs depends very much on the flow rate and pressure of the fluid. Large, high flow rate nozzles may hold a good approximation to the theoretical pattern at well over a meter from the nozzle. Conversely smaller, low flow rate nozzles that produce finer sprays may only hold true to the theoretical pattern for a few centimeters.

Viscosity

The viscosity of a fluid may affect the spray angle produced. Fluids that are less viscous than water will tend to have a wider angle and vice versa. The effect is generally small but worth checking if precise spraying is required. We have software that can calculate this effect if necessary.

Specific gravity

As noted above in the section on flow rates the specific gravity of a fluid affects the overall flow rate through the nozzle. Heavier fluids experience a reduced flow rate but the overall weight of the spray will be increased for any given pressure. This means that the theoretical pattern will actually hold better as the spray has more momentum. One can also think of this as the spray consisting or larger droplets with less energy being used to atomise the spray.

Pressure

Some nozzles maintain a steady spray angle regardless of pressure. Others will have patterns that vary with pressure. In particular, tangential whirl design nozzles will increase their angle of spray as pressure increases. This is because they work by forming a whirlpool of fluid within the nozzle which then is ejected by centrifugal forces into a hollow cone pattern. As pressure increases the centrifugal forces increase, lowering droplet size but increasing the angle at which they are dispersed. Conversely, a spiral design hollow cone nozzle will produce more or less the same spray angle regardless of pressure as it works by shearing the fluid into droplets by impact on the spiral shape.