Liquid distribution

The overall area pattern produced is generally not completely uniform. Some nozzles produce more even patterns than others so, for example, not all full cone patterns of one meter diameter will have the same liquid distribution even if the overall flow rate is identical.

Why is this important?

For applications like coating or moistening any localised areas of smaller of higher fluid distribution may result in problems. These types of application necessitate even spray patterns. Conversely some applications may actually require deliberately uneven patterns of distribution. For example, in fire fighting applications the presence of heavier concentrations of liquid in certain parts of the overall pattern helps give the spray momentum, helping to penetrate thermal currents and deliver the lighter smaller droplets in other parts of the pattern to the fire.

What affects liquid distribution?

This is essentially all down to the design of the nozzle. As mentioned above not all nozzles will produce the same distribution of fluid even though their theoretical spray patterns are identical. Some general rules of thumb that can be applied are:

- Spiral nozzles will produce concentric rings of spray that make their full cone pattern resulting in rings of concentration

- Tangential whirl nozzles can be configured to produce wide or thin hollow cone patterns depending on design

- Flat fan nozzles will produce a strip of spray but this will taper at each end meaning some overlapping may be required to form an even spray

The narrower the spray angle the more evenly distributed the liquid will be. As there is less opportunity for the fluid to spread out and form localised areas of higher concentration.

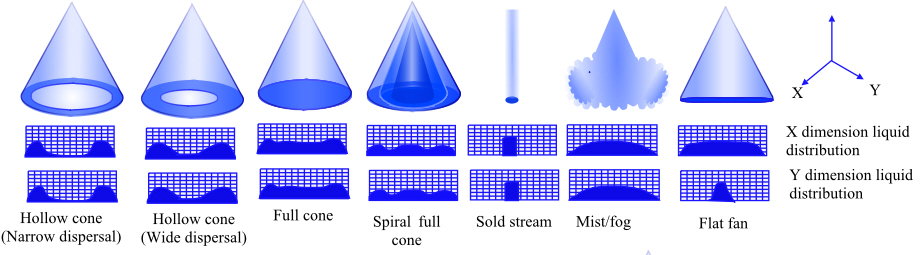

Liquid distributions for a variety of different spray patterns