Precision Spraying Guide

This is a short guide to some common precision spraying techniques that help improve product quality and reduce wastage in a wide variety of industries. Firstly, the guide differentiates the four different types of precision before going on to discuss

which spray nozzles need to be deployed to achieve each kind of precision. To read or download a pdf version, click the icon below.

What is precision spraying?

Precision in spraying applications comes in four main forms:

Spatial precision

This type of precision is ensuring that the spray only hits the area it needs to. Imprecise spraying will result in fluid being delivered to

areas where it is not required. In many cases, this will be simply wasteful of product but if, for example, glues are delivered outside the desired area, overspraying can have serious production consequences.

Dosing precision (flow rate)

It is one thing getting the spray on target but also the correct amount of spray needs to be delivered. This means control of the flow rate of spray nozzles needs to be achieved. Variations above or below the desired levels will result in either

product defects or wastage.

Consistency precision

Overall flow rates will affect the overall dosing but often thought needs to be given to spray distribution. The evenness of the spray over the area may be a

big factor in achieving a good quality product. The spray properties such as average droplet size and variations in spray densities across the spray pattern generated by the nozzle, therefore, need to be understood and controlled.

Temporal precision

With conveyor spray systems (or with any other systems with relative motion between the spray nozzle and the target) the spatial and dosing precisions mentioned above often translate to temporal precision. Controlling exactly when the nozzle comes

on and off will determine where and how much spray is delivered. Having a very crisp and sharp on/off cycle is, therefore, often critical in such systems. Temporal precision is vital in any stop/start spraying system.

Methods of control

Methods of control

Fluid pressure

The most basic form of control can be achieved by varying the fluid pressure. This will determine the overall flow rate through the nozzles. A simple pressure regulator will be enough to ensure that a consistent flow

rate is achieved. Pressure control may be enough for continual runs of product with no

on/off spray cycles required.

Air actuated nozzles

If stop/start cycles are required as part of a production run, then

air actuated spray nozzles will probably be required to achieve the desired level of spatial precision. A hydraulic valve for turning the fluid flow on and off directly will have a lag time before the nozzle is fully turned off and there will be some

dripping or poor spraying during this time. Air is far more responsive so an air actuated shut off system can be cycled on and off about 3 times per second. Fluid pressure is continually maintained so the spray is always “ready” to be

released. This will normally be responsive enough for most stop/start spray applications.

Air control

Air atomising nozzles mix fluid and air to produce fine sprays. The presence of air gives another variable

for controlling spray properties. The air mixed with the fluid also helps carry and direct the resulting spray. All this can help with both spatial and consistency control.

The spray properties including spray pattern and droplet size will

be determined by both the air and fluid pressure. As there are two variables, a greater degree of control can be achieved over the resulting pattern and consistency of spray. In some air atomising nozzles such as the SAM nozzle, different air feeds

are used to control the level of atomisation and the actual spray angle delivered. In such nozzles we now have three independent variables that can be used to control the spray (fluid pressure, atomising air pressure and spray pattern air pressure).

Electrically actuated nozzles

Nozzles with an integrated electric valve offer another level of control. These

nozzles have a built-in direct shut off system that opens and closes the nozzle orifice up to 150 times per second. Fluid pressure will be maintained. This means that very precise temporal control can be achieved whilst maintaining very good consistency

control. Of course, on conveyor systems, good temporal control translates to good spatial control.

Nozzles with an integrated electric valve offer another level of control. These

nozzles have a built-in direct shut off system that opens and closes the nozzle orifice up to 150 times per second. Fluid pressure will be maintained. This means that very precise temporal control can be achieved whilst maintaining very good consistency

control. Of course, on conveyor systems, good temporal control translates to good spatial control.

A further technique available to electric nozzles also allows for good dosing control. Pulse Width Modulation (PWM) takes advantage

of the very rapid on/off cycles available to electric nozzles. By pulsing the nozzle on and off very rapidly the flow rate from the nozzle can be reduced without compromising consistency precision. Normally if a nozzle was pulsed we would see a degradation

in the consistency of any coating produced, but with 150Hz pulsing no noticeable effects on consistency can be seen. So, with a 50% on to 50% off very rapid cycle we can reduce the flow rate from the nozzle by 50%

Conveyor speeds

Another way of controlling dosing precision is to vary the speed of conveyors. Slower conveyors will result in a higher dose being delivered and vice versa. Obviously, this control technique is only available to conveyor systems.

Mixed variables

Whilst all the control techniques above have their place, some are less suitable than others. Using fluid pressure to control dosing, for example, will affect spray properties other than just flow rate. So, spray angle and droplet size will also be affected

by changes in fluid pressure. This means that for variable product runs which require good spatial and consistency precision, using fluid pressure to control dosing will not be enough.

Similarly, when using air atomising nozzles even through

the additional variable of air pressure gives a wider scope of control, all features of the spray will be affected by the air fluid mix. As such, controlling dosing without affecting spray consistency can be difficult. Using external mix air atomisers

with independent air feeds for spray shape and atomisation helps solve this greatly. Nevertheless, if we wanted to reduce flow rate whilst keeping everything else consistent some complex calibration experiments would need to be performed. It can be

done, but it is not immediately obvious how changing one parameter will affect the others.

This sometimes complex interplay between spray variables is not really an issue with standard monolithic production runs. Initial calibrations

can be tricky but once the parameters are defined (fluid pressure, air pressure, on/off cycles etc) the production run can be set and left to run. Tweaks to calibration will, hopefully, be fairly few and far between so even if they are initially

tricky, this will not be a big problem in the grand scheme of things.

Variable production runs

When, however, variable production runs are required the complex interactions between spray input variables can be highly problematic. Imagine we have two different product runs both of which require the same consistency of spray and spatial delivery

of spray, but one run requires that half the dose is delivered. Varying fluid pressure by a factor of about 4 will change the flow rate by about a factor of 2 but a 4-bar spray will be very different in droplet size to the same fluid at 1 bar.

One solution would be to simply speed up the conveyor for the low dose production run. But this might not be possible and, if the high dose schedule is the main product, we are now effectively hobbling production of the main product line for the

sake of being able to reduce dosing for a minor product line. It is obvious why conveyor speed techniques are often far from ideal.

Air atomisers with independent air feeds for spray shape and atomisation could be used in such a situation. The initial calibration might be tricky but once the input parameters have been defined for each production run consistent results can be achieved. Fluid and air pressures are simply adjusted for each different production schedule.

An even

better solution would be to use the PWM technique discussed above. Electric nozzles can be cycled on and off very rapidly so that a consistent spray can be delivered at different flow rates. As none of the spray input variables change the spatial

and consistency precision is maintained. So, with electric nozzles different doses can be programmed; if the highest dose can be achieved by the 100% on spraying schedule while other, lower doses, can be delivered by the same nozzles spraying at the

same fluid pressure.

Conclusions

Precise spraying is important in a wide number of manufacturing processes. There are several advanced spray nozzle products available to achieve desired spraying even across variable production runs. Which techniques are most suitable will vary greatly

from situation to situation but the following universal conclusions can be made.

1- Consider each of the types of control listed above. The most appropriate control techniques can then be selected.

2- Consider the effects of

variable runs. The set of nozzles that will only need to cope with one spraying schedule may be different to the nozzles that will need to cope with several different production runs. Some thought upfront about this may save a lot of hassle later

on.

3- Deal with a specialist nozzle manufacturer that you trust. Cheap nozzles made by non-specialist companies will almost certainly have variable spray qualities. This makes precise control almost impossible. Just as important as the product

quality though is the expert advice that goes into making correct nozzle selection. A company that really understands spray technology will be able to offer sound and ultimately money-saving advice from the start.

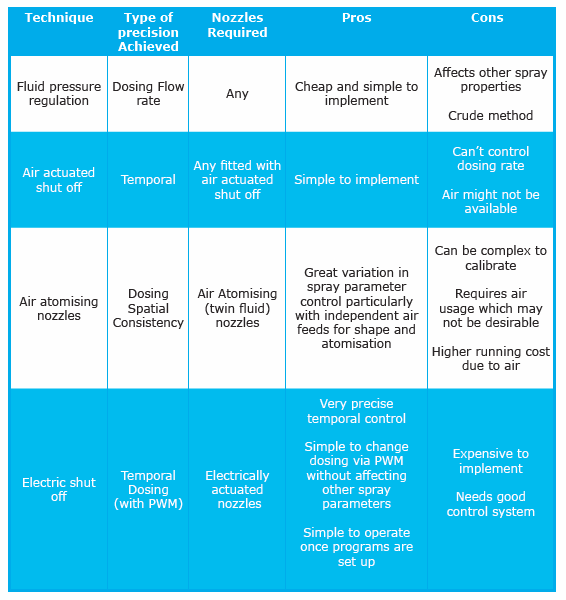

Table of precision spraying techniques