Spray coating applications

Coatings in bakeries take many forms. It can be a simple water spray designed to allow seeds to adhere to a roll or can involve the spraying of highly viscous fluids like chocolate. Whatever the fluid properties SNP will have a nozzle system that can cope.

The need for control

Successful coating applications typically come down to one main factor - control. Being able to control the flow rate, drop size and spray pattern will ensure successful and efficient spray coating. Good control is vital for product quality and to reduce the waste of often expensive coating ingredients.

Depending on the type of coating systems deployed different levels of control will be required. Below we have separated coating systems into two commonly found types in bakeries.

1 Continuous conveyor

1 Continuous conveyor

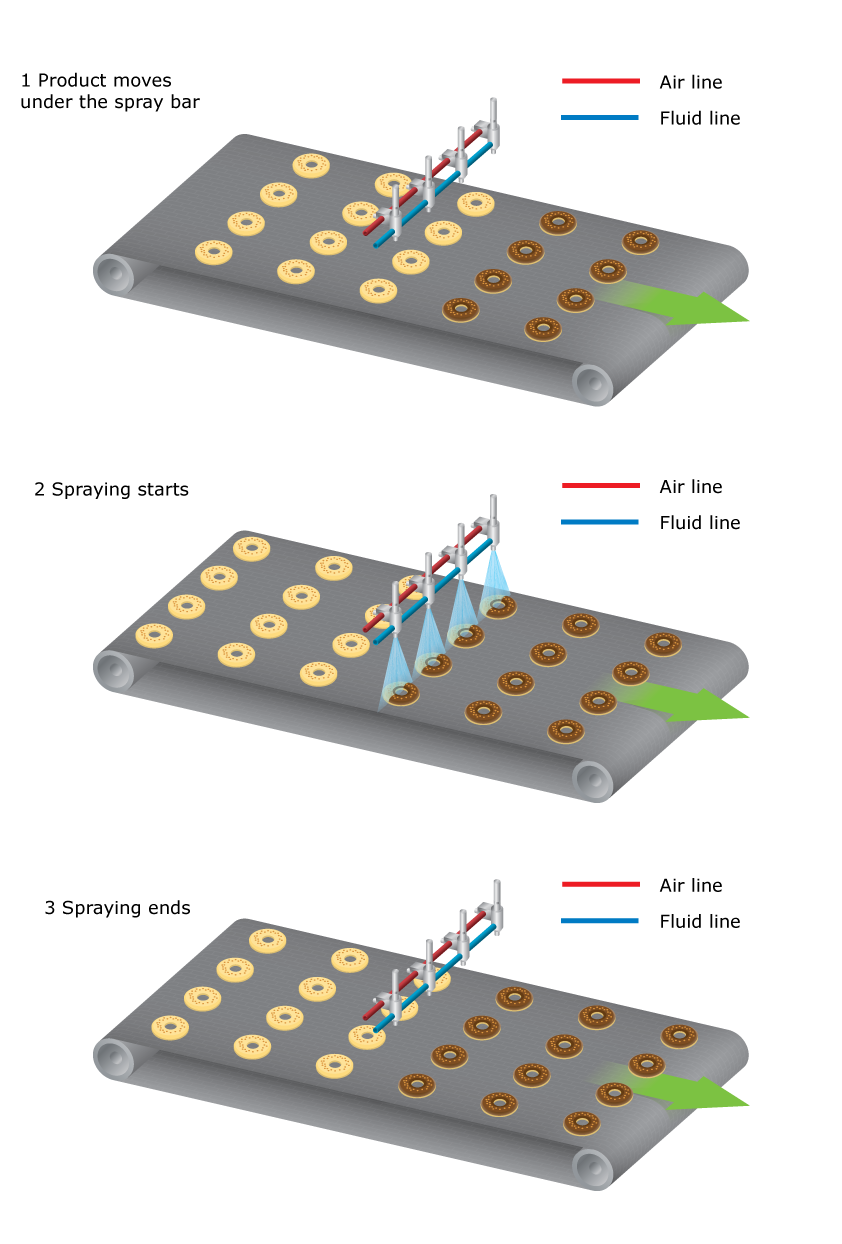

Typical coating applications will involve a spray bar deployed over a product conveyor. A line of spray is produced and the motion along the conveyor ensures the entire product is coated as it passes under the spray bar. Normally such setups deploy flat fan nozzles.

Whilst the conveyor will be moving continuously the product may be spaced at intervals. This means that spraying may only be required when a product passes under the spray bar. If the process is fast-moving then such systems will require precise control and this will often mean air actuated spray nozzles are required or electrically actuated nozzles.

Dosing

Dosing can be controlled by the flow through the nozzle as well as by the speed of the conveyor. With electrically actuated nozzles dosing can also be controlled via pulse width modulation. Such nozzles can be cycled on and off 150 times per second. So by using very rapid on/off cycles flow can be reduced without affecting the continuity of the coating.

Nozzle selection

For simple continuous spraying systems hydraulic flat fan nozzles may be suitable. (Please click on the nozzle icons below to access data sheets).