Coating applications for food processing

The use of sprays to coat products on a process line is a critical application in many food production lines. This can be as simple as a water spray to allow the adhesion of seeds in a bread roll production line to more complex coatings of heated viscous fluids like chocolate or peanut butter.

The variety of fluids being used in spray coatings in the food industry presents some challenges and warrants a large product range to accommodate the differences in fluid properties. SNP have access to not only a huge variety of nozzles but also to decades of industry experience which means we have the knowledge to marry the correct nozzle to your unique application.

Precision spraying

A successful spray coating system is all about precision. Too little product and the coating will not work as intended resulting in quality issues. If too much liquid is applied then the product can also be ruined and at the very least it will result in a wasted spray and so wasted money.

A successful spray coating system is all about precision. Too little product and the coating will not work as intended resulting in quality issues. If too much liquid is applied then the product can also be ruined and at the very least it will result in a wasted spray and so wasted money.

Precision spraying has three key components: dosing, accuracy and spray properties.

The correct dosing can be achieved by having precise control over the timings of the spray set up so air actuated shut-off systems are commonly used. But dosing also necessitates a high quality nozzle that will ensure the flow rates stated on the datasheets will be met.

This often requires expert advice from the nozzle vendor particularly when the fluid being sprayed has different properties to that of water. SNP have experience in spraying a wide variety of different fluids and so can give meaningful advice on correct dosing.

Correct dosing is all for nothing if the fluid ends up in the wrong place. Configuring a spray set up to ensure the spray is on target can sometimes be difficult. As with dosing, issues can arise if careful consideration is not given and if a fluid with properties very different to water is being sprayed. Most nozzle spray angles and flow rate charts will be calibrated with water and numbers on these charts will vary considerably with many of the spray coatings used in food production.

The control of spray properties can be complex. Often the droplet size is a critical variable in coating applications as this can greatly affect the adhesion of the coating. A spray with a smaller droplet size will have a greater overall surface area to volume and so will generally adhere to its target better. Droplet size, however, is controlled by fluid pressure and, in the case of air atomising nozzles, air pressure. These variables also normally affect the flow rate and spray pattern so making independent adjustments to droplet size can be difficult.

The control of spray properties can be complex. Often the droplet size is a critical variable in coating applications as this can greatly affect the adhesion of the coating. A spray with a smaller droplet size will have a greater overall surface area to volume and so will generally adhere to its target better. Droplet size, however, is controlled by fluid pressure and, in the case of air atomising nozzles, air pressure. These variables also normally affect the flow rate and spray pattern so making independent adjustments to droplet size can be difficult.

External mix air atomising nozzles are a partial solution to this problem as the flow rate of the nozzle is independent of the air atomising feed. The level of atomisation can thus be dictated by changing the air feed pressure without affecting the fluid flow rate through the nozzle. However, this will still vary the shape of the spray and so complete control is not achieved.

A complete solution to the problem is our SAM range of nozzles. These air atomising nozzles have three air inlets. One controls the atomisation level (droplet size), the next controls the shape of the spray (pattern) and the final controls the spray on/off cycle. The flow is controlled by the fluid feed pressure. With four inlet variables, SAM nozzles represent the ultimate in spray control and allow for micro-adjustments in droplet size, pattern, flow rate and cycle time to be made between batches. These adjustments can be critical in optimising coating applications for variable batches. When linked to the correct sensors and valves, a highly responsive spraying system can be achieved that can automatically adjust to variation.

Controlled spraying

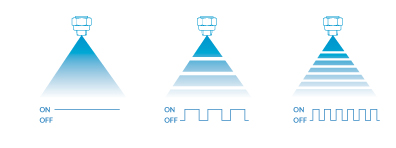

Often the spraying process is not continuous. Stop/start spraying requires a nozzle that can rapidly cycle on and off without losing its spray quality. Purely hydraulic nozzles are generally not responsive enough to the rapid cycles demanded by many food processing plants.

Air actuation or electric shut-off systems will give the required precision. With these nozzles the fluid is kept continuously under pressure and the nozzle is activated by air overcoming a shut-off pin or with an integrated electric shut off valve. This allows the nozzle to be cycled on and off very rapidly. The resulting spray is more or less instantaneously of the correct flow, pattern and droplet size, meaning consistent and precise amounts of spray can be delivered.

With air-actuated nozzles the spray nozzles themselves can be either air atomised or can be hydraulically generated sprays with an air-actuated shut off. Electric nozzles will have a standard hydraulic spray nozzle.

A further advantage of electric nozzles only is the ability to perform pulse width modulation. These nozzles can be cycled on and off up to 150 times per second. This means that if very rapid pulsing of on/off cycles is programmed the nozzles will deliver less fluid but, because the cycle is so rapid, there will be no noticeable difference in the continuity of the spray. So, a continual even coating will still be delivered. By using this technique, the same nozzles spraying at the same fluid pressure can deliver variable flow rates. As the fluid pressure remains the same, other spray characteristics, such as droplet size, remain constant.

Control system

Electronic nozzles can be linked to our FlexFlow control system. This can be used to precisely set the on/off cycle, the pulse width modulation, the frequency of modulation, delays in spraying cycles, and much more. Furthermore, it can be linked to a wide variety of sensor inputs to give the ultimate control.

Electronic nozzles can be linked to our FlexFlow control system. This can be used to precisely set the on/off cycle, the pulse width modulation, the frequency of modulation, delays in spraying cycles, and much more. Furthermore, it can be linked to a wide variety of sensor inputs to give the ultimate control.

For more information on the FlexFlow control system for electronic nozzles please click here