Tank cleaning for the food and beverage industry

The variety of tanks and vessels that need cleaning in the food and beverage industry is staggering. This fact, combined with the equally varied types of residues that need to be cleaned, means a correspondingly large variety of tank cleaning heads are needed to ensure optimised cleaning for each situation. SNP have just such a range with tank cleaning heads suitable for any size and shape of tank and any conceivable residue, no matter how tough.

Optimising tank cleaning for the food and beverage industry

Often water is wasted in CIP tank cleaning systems. The default spray balls supplied with the vessel will generally be an afterthought and are often inefficient. Efficiency gains can be made by correct cleaning head selection. Often the same or better level of cleaning can be achieved in less time by changing the type of cleaning head deployed. This can, in many cases, be achieved without changing feed pumps or pipework. Please read the technical article linked here for a detailed look on tank cleaning optimisation.

Types of tank cleaner

We divide our range into four main groups:

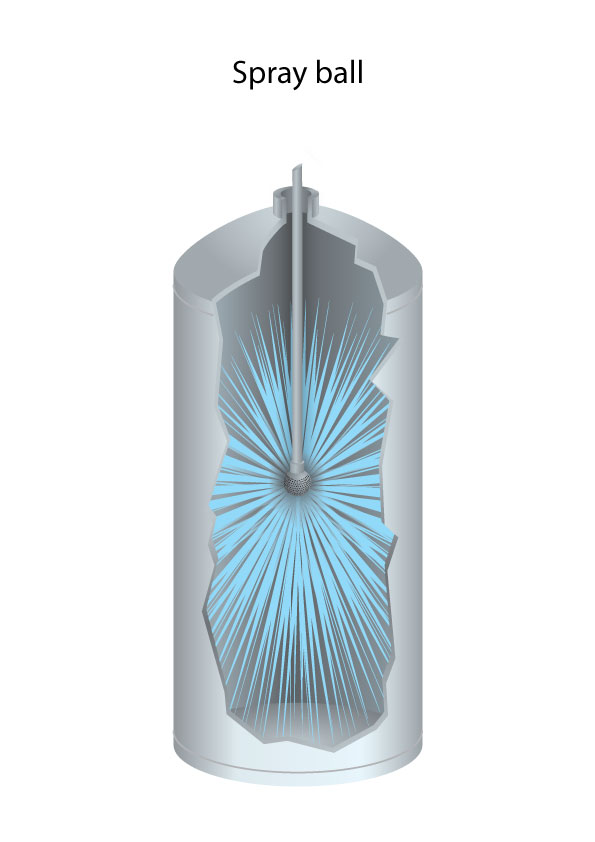

Static tank cleaner  are nozzles with no moving parts. Most commonly this will be a spray ball type of tank cleaner consisting of a sphere with multiple holes producing many micro-jets of low impact cleaning fluid. Other types of static tank cleaners include wide angle spiral nozzles and nozzle manifolds consisting of multiple full cone spray nozzles pointing in different directions.

are nozzles with no moving parts. Most commonly this will be a spray ball type of tank cleaner consisting of a sphere with multiple holes producing many micro-jets of low impact cleaning fluid. Other types of static tank cleaners include wide angle spiral nozzles and nozzle manifolds consisting of multiple full cone spray nozzles pointing in different directions.

These types of cleaner, although water inefficient, are simple to install, low cost and reliable. This makes them the most widely used type of tank cleaning device in the food and beverage industry. SNP have a full range of spray balls and other static nozzle systems although for most applications we tend to recommend using the more efficient rotary cleaning heads detailed below.

This range now also includes the new HydroClaw, clog-resistant tank cleaner. The HydroClaw is a new innovation in tank cleaning that gives a robust 360 degree cleaning pattern but is able to cope with recirculated cleaning fluid that may be contaminated with pips, stems or fruit skins that would normally block traditional spray balls.

Please click on the boxes below to access tank cleaner data sheets