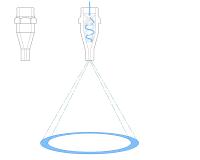

Axial whirl hollow cone nozzles

With this design of hollow cone nozzle the fluid is set into a whirl motion by an internal vein or whirl chamber. The resulting turbulence breaks up the liquid into droplets which are then shaped in to a hollow cone pattern as they exit the orifice.

This design of nozzle can also be used to produce a full cone pattern. Which pattern is ultimately produced - full or hollow - is down to the differences in the geometry of the whirl chamber. Hollow cone whirl chambers allow the natural centrifugal forces of the rotating fluid to concentrate the liquid into ring shaped pattern.

BETE produce a number of different axial whirl hollow cone nozzles with different features. Full product information can be found by clicking on the relevant box below.

To compare the features of all hollow cone nozzles please access the hollow cone nozzle cheat sheet by clicking on the orange button to the right hand side of this page.