Spiral hollow cone nozzles

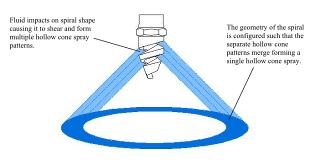

The spray pattern is formed by impacting the fluid onto a protruding helix after exiting from the spray orifice. The liquid then shears off the helix, breaking into droplets and forming the spray pattern. Spiral nozzles are often used to produce a full cone pattern but this is actually made up of concentric overlapping hollow cone patterns, so with careful crafting of the spiral geometry the concentric patterns can be made to completely converge giving a single hollow cone.

Spiral nozzles will, for any given flow rate and pressure, produce a hollow cone spray with the smallest droplet size of any direct pressure nozzles.

A big advantage of this design, over the axial whirl, is that it is clog-resistant allowing a wider range of fluids to be sprayed. As the fluid is broken up into the spray pattern after exit from the orifice these nozzles have a very large free passage meaning gritty contaminants will easily move through the nozzle without causing blockages.

BETE produce a number of different spiral design hollow cone nozzles with different features. Full product information can be found by clicking on the relevant box below. Please note that these nozzles are also available in full cone configuration.

To compare the features of all hollow cone nozzles please access the hollow cone nozzle cheat sheet by clicking on the orange button to the right hand side of this page